With its promise of lightning-fast data transmission and increased bandwidth, fiber optics can revolutionize your company's connectivity. Encom Services has been working with fiber optics for years, designing, building, and certifying fiber networks. If you believe an upgrade to fiber is in your future, understanding the key aspects of the technology will help you make informed decisions. This article will guide you through the essential components of fiber optic systems. When you are ready to make the move to fiber, we can help.

Multi-mode vs. Single-mode Fiber: Choosing the Right Type

When considering fiber optic cabling, one of the first decisions you'll face is choosing between multi-mode and single-mode fiber. Each has its strengths and is suited to different business needs.

Multi-mode Fiber: The Short-Distance Sprinter

Multi-mode fiber (MMF) is designed for shorter distance transmissions, making it the right choice for many business environments. Here's what you need to know:

- Distance: Effective up to 2 km, ideal for most office buildings and campuses.

- Cost-effectiveness: Uses less expensive light sources and connectors, potentially reducing your initial investment.

- Bandwidth: While lower than single-mode fiber, it's still more than adequate for most business applications.

- Best for: Local Area Networks (LANs), data centers, and connections between buildings on a single property.

If your business operates within a single location or a close-knit campus, multi-mode fiber could be your go-to solution. It offers a balance of performance and cost that suits many corporate environments.

Single-mode Fiber: The Long-Distance Champion

Single-mode fiber (SMF) is optimized for long-distance transmissions, making it the choice for businesses with more extensive networking needs:

- Distance: Can transmit data over 100 km or more, connecting multiple locations across a city or region.

- Bandwidth: Offers the highest bandwidth capabilities, future-proofing your network for upcoming technologies.

- Cost considerations: Requires more expensive light sources and connectors, but the extra cost may be justified for businesses requiring long-distance, high-bandwidth connections.

- Best for: Connecting multiple office locations, linking to off-site data centers, or preparing for significant future bandwidth needs.

If your business has multiple locations or anticipates substantial growth in data needs, single-mode fiber could be a wise long-term investment.

Fiber Optic Cable: Loose Tube vs. Ribbon Fiber

The structure of your fiber optic cable can impact its durability, ease of installation, and suitability for different environments. Let's compare two common structures:

Loose Tube Fiber: Versatile and Robust

Loose tube fiber cables contain several buffer tubes, each housing multiple fiber strands that can move freely. This design offers several advantages:

- Environmental protection: Better resistance to temperature changes and physical stress, making it ideal for outdoor and underground installations.

- Flexibility: Allows for easier mid-span access, useful for branching connections to multiple offices or floors.

- Best for: Businesses with outdoor networking needs or those requiring connections between buildings.

Example: If you're connecting multiple buildings on a corporate campus or industrial park, loose tube fiber could provide the durability and flexibility you need.

Ribbon Fiber: High Density and Efficiency

Ribbon fiber cables contain fibers arranged in a flat, ribbon-like structure, offering their own set of benefits:

- Space efficiency: Higher fiber density in a smaller cable diameter, perfect for locations where space is at a premium.

- Faster installation: Allows for quicker mass fusion splicing, potentially reducing downtime during installation or repairs.

- Best for: Data centers, high-capacity networks, or any situation where you need to run many fibers in a confined space.

Example: If you're setting up a server room or data center and need to run hundreds of fiber connections in a small area, ribbon fiber could be the ideal solution.

Connecting Fibers: Mechanical vs. Fusion Splicing

When it comes to joining fiber optic cables, you have two main options: mechanical splicing and fusion splicing. Understanding the differences can help you plan for installation and maintenance.

Mechanical Splicing: Quick and Accessible

Mechanical splicing involves aligning and joining fiber ends using a physical mechanism:

- Speed: Quicker to perform, reducing installation time and costs.

- Equipment: Requires less expensive tools, making it more accessible for smaller businesses.

- Performance: Higher signal loss compared to fusion splicing, which may impact long-distance or high-bandwidth applications.

- Best for: Temporary repairs, small-scale deployments, or situations where fusion splicing equipment isn't practical.

Fusion Splicing: High Performance and Reliability

Fusion splicing uses heat to melt and fuse fiber ends together:

- Performance: Offers the lowest signal loss and highest reliability, crucial for critical business networks.

- Long-term value: While initially more expensive, the superior performance can lead to long-term savings through improved network efficiency.

- Expertise required: Needs skilled technicians and more expensive equipment, which may influence your choice of installation provider.

- Best for: Permanent installations, high-performance networks, and businesses where network reliability is mission-critical.

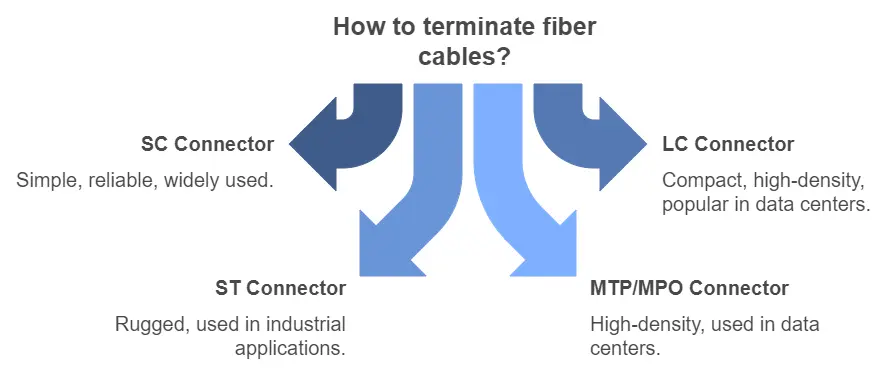

Fiber Cable Termination: Putting It All Together

The way your fiber cables connect to network equipment can impact performance, ease of maintenance, and future flexibility. Here are the main termination methods to consider:

- Field-installable connectors: Quick to install but may have variable performance. Suitable for smaller deployments or where rapid installation is crucial.

- Pre-terminated cables: Factory-terminated for consistent quality. Ideal if you know exact cable lengths needed and want to minimize on-site work.

- Pigtail splicing: Combines factory-terminated short cables with field splicing. Offers a balance of performance and flexibility, suitable for most business environments.

- Mechanical splice-on connectors: Faster than traditional splicing with better performance than basic mechanical connectors. A good middle-ground for many business applications.

- Fusion splice-on connectors: Offers high performance with the convenience of a connector. Ideal for businesses prioritizing network quality and willing to invest in the best termination method.

Making the Right Choice for Your Business

When planning your fiber optic deployment, consider these factors:

- Current and future bandwidth needs: Will multi-mode fiber suffice, or should you invest in single-mode for future-proofing?

- Physical environment: Are you connecting multiple buildings or focusing on a single facility? This will influence your choice between loose tube and ribbon fiber.

- Budget and long-term plans: Weigh the initial costs against long-term performance benefits when choosing splicing and termination methods.

- In-house expertise: Do you have the skills to maintain the network, or will you rely on external providers?

By understanding these key aspects of fiber optic technology, you're better equipped to make decisions that will serve your business now and in the future. Remember, the right choice depends on your specific needs, environment, and growth plans. Don't hesitate to consult with the fiber optic specialists at Encom Services. We will help you tailor a solution that is right for your specs.

Investing in fiber optics is more than just an upgrade to your network – it's an investment in your business's future connectivity and capabilities. Remember Encom Services when you're ready to take the next steps in bringing the power of fiber optics to your organization.