Fiber optic splicing is a crucial skill we train all our technicians to perfect. At times, we wish we could train our clients the same methods so they could understand how well their network infrastructure is built. This guide explores the primary methods, best practices, and essential considerations for successful fiber splicing.

What is Fiber Splicing?

Fiber splicing is the process of joining two optical fibers end-to-end to create a continuous light path. Unlike conventional electrical connections, fiber splicing requires precise alignment at the microscopic level to minimize signal loss and maintain data integrity.

There are two basic approaches to fiber optic splicing. Fusion splicing uses heat to melt fibers together while mechanical splicing physically aligns and holds the fibers in place using specialized hardware. Each method has its advantages. Let’s look at them in detail.

Fusion Splicing

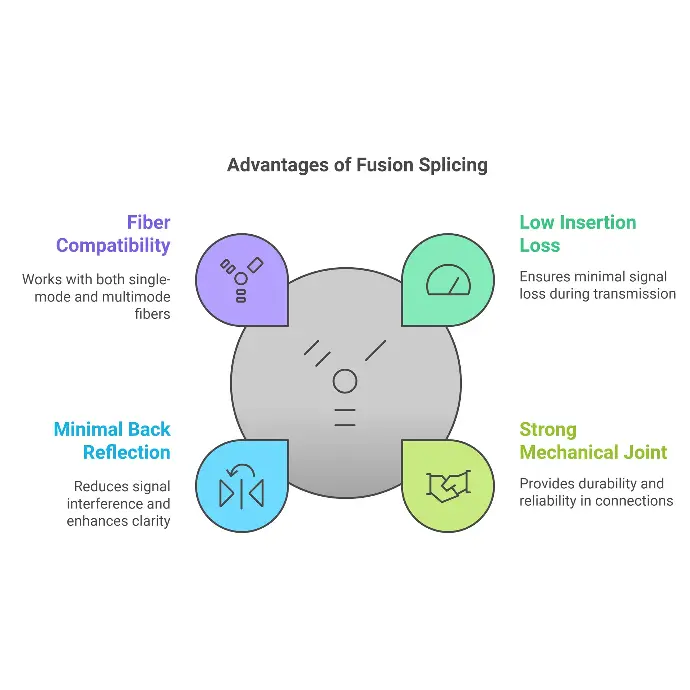

Fusion splicing uses an electric arc to melt and fuse fiber ends together, creating a seamless connection. This method typically produces the lowest loss and highest strength joints.

Key steps:

- Strip and clean fiber coating

- Precision cleave the fiber ends

- Align cores using microscope imaging

- Generate electric arc to melt and fuse

- Apply protection sleeve

Advantages:

- Lowest insertion loss (typically 0.01-0.10 dB)

- Strongest mechanical joint

- Minimal back reflection

- Suitable for single-mode and multimode fibers

Mechanical Splicing

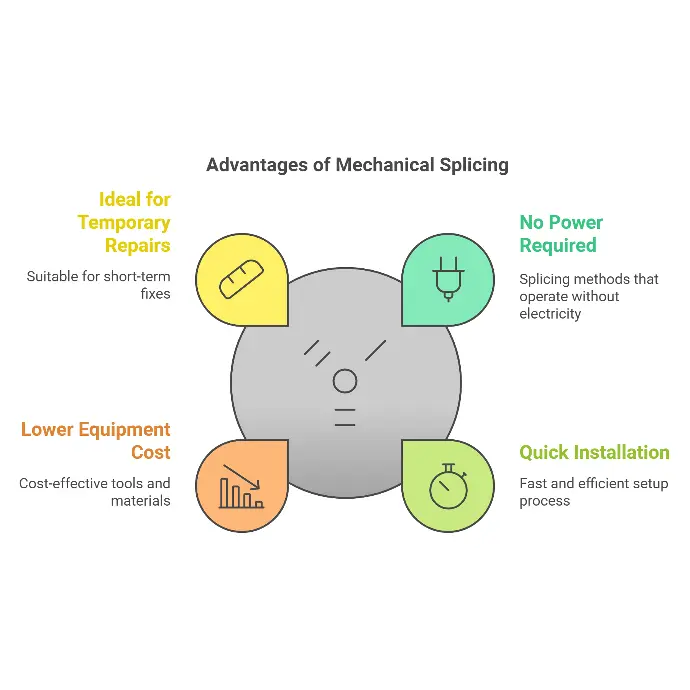

Mechanical splicing uses precision-made alignment mechanisms and index-matching gel to join fibers without fusion.

Components:

- Alignment sleeve or V-groove

- Index-matching gel

- Clamping mechanism

- Protective housing

Advantages:

- No power required

- Quick installation

- Lower equipment cost

- Ideal for temporary repairs

Successful fiber splicing requires attention to detail, proper equipment, and adherence to best practices. Whether choosing fusion or mechanical splicing, understanding these fundamentals ensures reliable optical network connections.